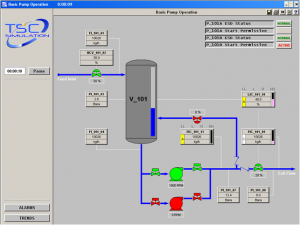

Oil & Gas Simulator : Basic Control Principles : Basic pump system

This is a short course (2hrs) hands-on process simulation operating Oil & Gas plant using our professional simulators.

This is a short course (2hrs) hands-on process simulation operating Oil & Gas plant using our professional simulators.Anyone can use the simulators, guided by our engineer-tutor. We have 5 simulators.

These sessions are 'hands-on' with our process simulators, which provides a safe environment to start-up, fault-find and shutdown the production process.

A certificate of successful completion will be issued, which could contribute towards a company competence assurance system.

Don't see the dates you are after, then please just contact us on admin@early.engineering or 01356-626006 or just walk in and book

Or use our ENQUIRY form here

We have a set of mobile laptops that we use for process simulator training : we can travel globally to deliver training. From awareness & introductory level for anyone, to complex offshore models we can cater for all. The process simulators ‘standard’ models cover:

• Basic Control Principles

• Complex Control Principles

• Basic Plant Subsystems

• Basic Plant Systems

• Complete plants -onshore or offshore

Steady state operations on process plant prevents many technicians/supervisors from learning basic start-up and shutdown procedures and processes, as well as maintenance isolations and fault finding. Our simulator based training allows delegates to work on process plant with total safety and freedom exploring areas such as alarm, trip & ESD envelopes. The simulator environment allows the instructor to introduce faults, providing delegates with experience and confidence to approach on-plant activities.

Within the training room we can provide training and assessment from basic systems through to complete plant start-up / shutdown and fault finding. The basic models take ~3 hours per candidate, with complex training courses lasting several days.

Venue

the HUB : Brechin

27a Panmure Street

Brechin

Angus

DD96AR

27a Panmure Street

Brechin

Angus

DD96AR